Bulletproof vests are but one piece of body armor that protects police officers day-in-day-out. They are commonly made from a material called Kevlar, which apart from also being found in military grade body armor, can appear in frying pans, parachutes, sneakers, tennis rackets and smartphones.

Bulletproof vests are made of long strips of interwoven fibers, normally Kevlar fibers, that are also layered on top of each other. This creates a tough barrier that disperses the mechanical energy and impact force of a bullet, effectively neutralizing it. There is still a destabilizing jerk and pain to the wearer on impact, but the bullet is stopped from penetrating the body.

Developed and patented by chemist Stephanie Kwolek in 1966, Kevlar, or poly-paraphenylene terephthalamide, was a project initiated by DuPont. The chemical company wanted to create stronger, yet more lightweight versions of the steel wires being used for car tires. Kevlar was born and has served law enforcement valiantly for over half a century. It can withstand high temperatures, does not corrode and does not rust. However, like with Kwolek’s curiosity, many inventors are now itching to find ways to make body armor tech more cost-effective, lighter and perhaps even supersede Kevlar’s five-year lifespan.

Also because, bulletproof vests aren’t really bulletproof. There are a handful of unfortunate incidents a year where a bullet is able to pierce the body armor and access the human flesh below it. Sometimes by pure luck, and sometimes due to special bullets that sport serrated edges. It’s also possible that, sometimes, the bullet does not penetrate but can cause fatal injury to internal organs.

The following areas are being investigated to eliminate this vulnerability.

Armor from natural sources

Lobsters

MIT researchers are investigating a type of protective material that could be flexible enough to not only protect the chest area, but also body joints that are critical for mobility in combat, such as the knees and elbows. Researchers are working on the armor while not only thinking of the shielded party walking, but also of scenarios where they would have to run, climb or swim.

The material that will be used to create this revolutionary spiderman-like technology: lobster exoskeleton. Upon study, the fibers in these membranes were found to dispel energy when “under attack or stress.” An armor that behaves like this could intuitively fight back even while the wearer does nothing, potentially whilst they are disoriented by a blast or focused on defending themselves from another threat.

Mushrooms

This time at the University of Houston, researchers (with funding from the US Department of Defense) are exploring a material made from mushrooms that could coat armor and hold up against poisonous gases, lasers, and the most common foe to law enforcement: bullets. The material, called chitin, is biodegradable and could be a welcome substitute for the use of plastic in armor, environmentalists hope. The Defense Department is hoping to mass produce the finished product using 3D printers.

Human Hair

Researchers at the University of California, this time with financial backing from The Air Force Office of Science Research, executed a study on the strength of human hair, with the intention of using their findings to develop hair care products and body armor. They found that, before it breaks, human hair can: stretch up to one and a half times its length; withstand temperatures of 140°F; and possess a strength and weight ratio comparable to that of steel. It was found that the faster that hair is stretched, the stronger it becomes. Research is ongoing, as the scientists moved on to test one of the weakening agents of hair: H₂O.

Liquid armor

Shear-Thickening Fluid (STF)

Moratex Institute of Security Technologies in Poland has created a non-Newtonian fluid that is more comfortable to wear than Kevlar and, allegedly, more effective at negating the effects of a gunshot. What is a non-Newtonian fluid? Simply put, Newtonian fluids do not change their properties when pressure is applied. Water is an example. If you push it around, it moves easily and remains the same consistency. A non-Newtonian fluid becomes more viscous as pressure is applied, even changing from a liquid to a solid.

Reuters noted, “When hit by a high-speed projectile, a wide area of the STF hardens instantly, causing the usually massive energy to be dispersed away from the wearer’s internal organs.” Only Moratex knows the composition of this fluid, however, and as of now, the armor technology is not widely available in the US.

METAL Foam

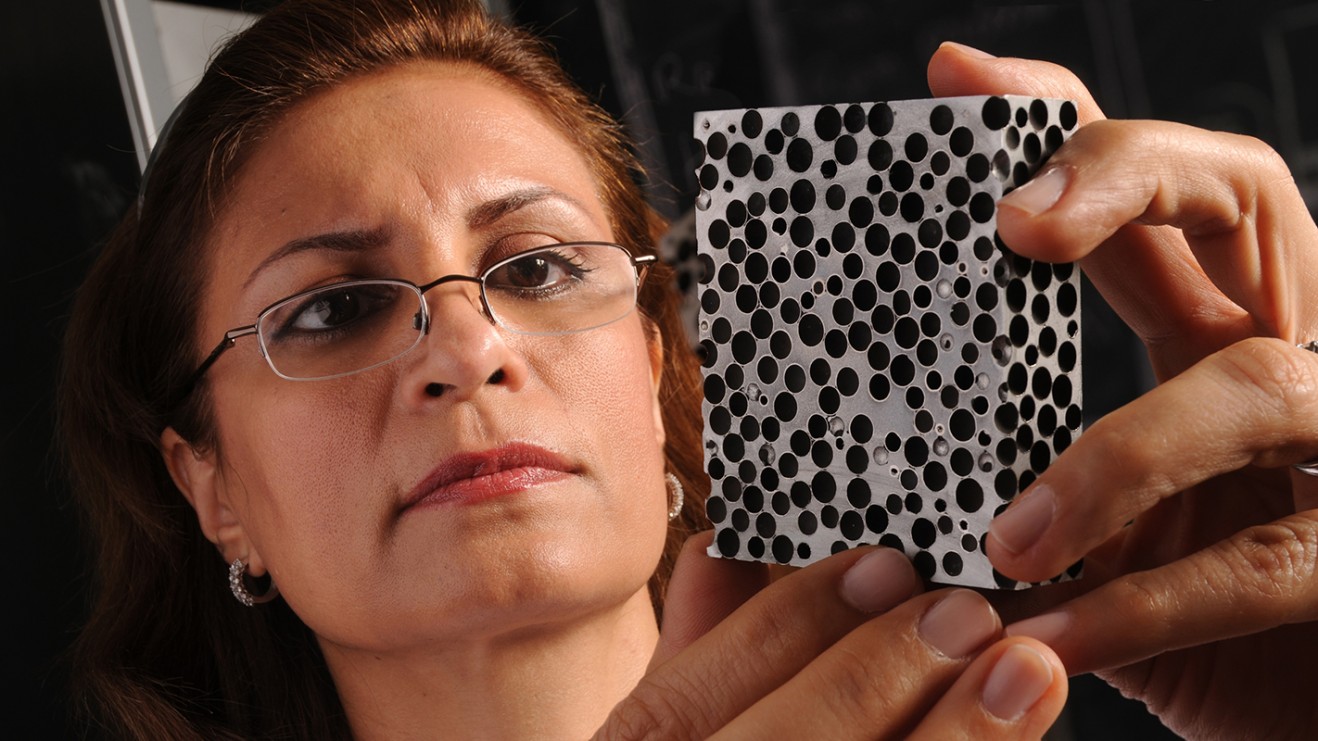

Returning to the East Coast of the USA, a University of North Carolina research team, headed by Afsaneh Rabiei, examined a type of foam that can pulverize bullets. The substance named CMF (Composite Metal Foam) has amazing properties and defense potential. It is made from stainless steel but has a more constant rate of expansion under high heat than the metal, and we’re talking about temperatures of over 392°F.

Afsaneh Rabiei (image source: news.ncsu.edu)

Of the material, Rabiei says, “Our findings suggest that CMF can offer extremely good thermal insulation, superior thermal stability, and excellent flame retardant performances as compared to commercially available materials such as stainless steel.” Not only can it do all that, but it can turn bullet rounds into powder upon impact. This material is so strong that it can be used not only in body armor, but is also being considered to contribute to the outer shell of armored vehicles.

Improving already existing armor

Cadet 1st class, Hayley Weir, has created a solution that could be used to improve existing body armor designs, by developing another non-Newtonian fluid that could be flattened and inserted into a portion of Kevlar. The solution was very shown to be successful during testing, preventing a round from a .44 magnum (used to hunt elephants) from piercing a piece of body armor.

The Cadet made headlines, as it was stated that, “because it could stop that round, the material could be certified as type 3 body armor, which is usually worn by Air Force security personnel.” The material is still under development, with no designated use currently assigned. However, it has been said that it could be used “as a protective lining on vehicles and aircraft and in tents to protect their occupants from shrapnel or gunfire.” BAE Systems in Canada (but headquartered in the UK) is working on a similar ‘custard’ type product.